Key Features

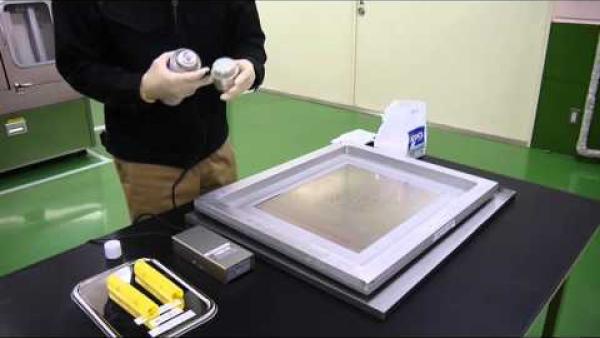

Precision Fine Pitch Aperture Cleaners

- Thousands of dollars less than fully-automatic cleaners

- Low solvent usage and running costs

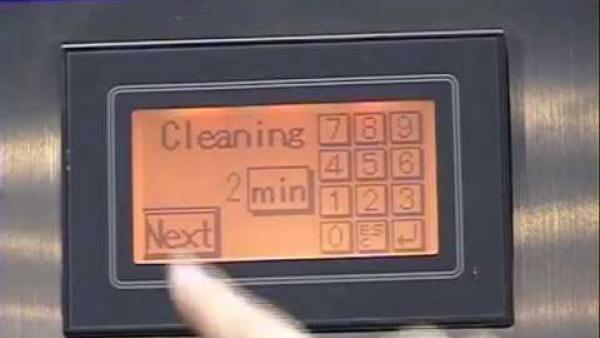

- Fast cleaning time of 1-3 minutes

- Minimal waste disposal

- Portable unit can be used directly on the screen printer

- Capable of cleaning squeegees, scrapers and misprinted PCBs

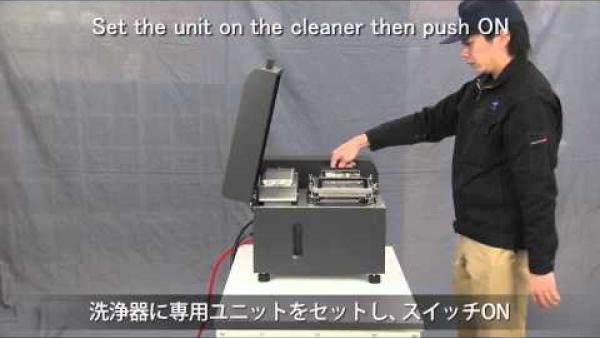

Sawa Stencil Cleaners are widely used in the Japanese Electronics Industry to ensure high yields when screen printing solder paste onto printed circuit boards. Normal cloth wipe cleaning of stencils cannot completely remove solder paste especially in fine pitch applications as a small amount of solder balls have a tendency to adhere in the corners of the apertures. Sawa Stencil cleaning machine are able to completely remove solder paste utilizing ultrasonic vibration and require no special solvents as they work effectively with isopropyl alcohol, water base solvent or any other solvent.

Stencil After Cloth Wipe Cleaning

SEE THE DIFFERENCE !

Look at this example of a conventional Cloth Wipe Stencil Cleaning.

Conventional cloth wipe cleaning cannot completely remove solder paste. Solder balls have a tendency to adhere to the corners of apertures.

Cleaning by Sawa Stencil Cleaner